Recently, a research team led by Professor Kang Feiyu, Professor He Yanbing, Associate Professor Lv Wei, and Assistant Professor Hou Tingzheng from the Institute of Materials Research at Tsinghua Shenzhen International Graduate School (Tsinghua SIGS), in collaboration with Professor Yang Quanhong's team from Tianjin University, has made new progress in the field of solid-state lithium metal batteries.

They innovatively proposed the design concept of a ductile inorganic-rich solid-electrolyte interphase (SEI). Their paper, titled A ductile solid electrolyte interphase for solid-state batteries, was published online in Nature. This marks the fourth Nature paper published by Tsinghua SIGS this year.

Solid-state lithium (Li) metal batteries are among the most promising candidates for both electric vehicles and large-scale energy storage systems. However, the uncontrolled growth of Li dendrites under practical conditions (high areal capacities and high current densities) severely hinders their commercial applications. Although extensive research has significantly improved the ionic conductivity of solid electrolytes, solid-state batteries are still prone to issues such as interfacial cracking under demanding conditions like high current densities and low-temperature charging and discharging.

Previous studies have generally concluded that lithium fluoride (LiF)-rich lithiophobic SEIs show a high Young’s modulus. However, the lithiophobic nature and inherent brittleness of traditional inorganic components lead to much larger Li+ nucleation barriers and difficulty in maintaining integrity during Li+ deposition and stripping at high current densities and areal capacities, ultimately causing severe Li dendrite growth, side reactions and interfacial cracking—a problem that remains effectively unresolved to this day.

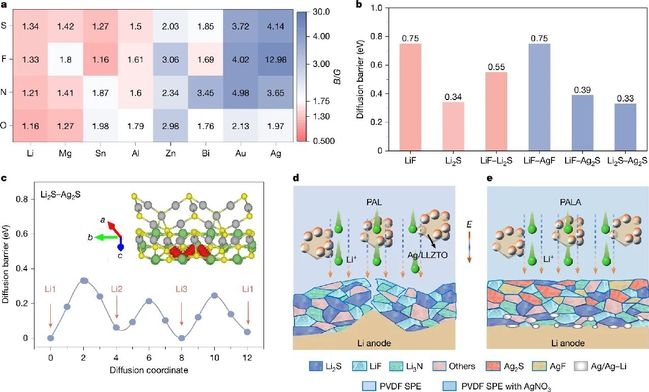

Figure 1. Design of the ductile SEI and its function in solid-state battery operation.

The research team developed the ductile inorganic-rich SEI that integrates exceptional mechanical properties, efficient lithium-ion transport kinetics, and multi-layer lithiophilic/lithiophobic characteristics, significantly enhancing the cycling stability of solid-state batteries under high current densities and low-temperature conditions.

The research team pursued innovation at the fundamental level of SEI structure and modeling, abandoning the conventional strength-only structural model and design philosophy for SEI. Instead, they prioritized ductility as the core criterion for screening new SEI components. Using the Pugh's criterion (B/G ratio ≥ 1.75 indicates ductility, where B is bulk modulus and G is shear modulus) as the ductility benchmark, they conducted an AI-accelerated theoretical screening of a series of potential inorganic materials. This process revealed that materials such as silver sulfide and silver fluoride not only exhibit excellent plastic deformation capability but also significantly reduce the diffusion energy barrier for lithium ions.

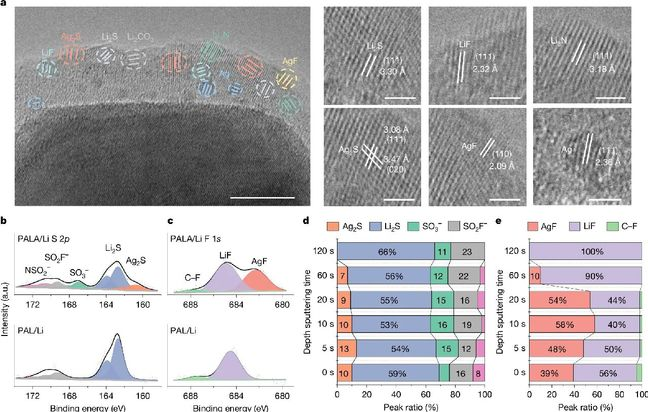

Figure 2. Structure and component analysis of the ductile inorganic-rich SEI.

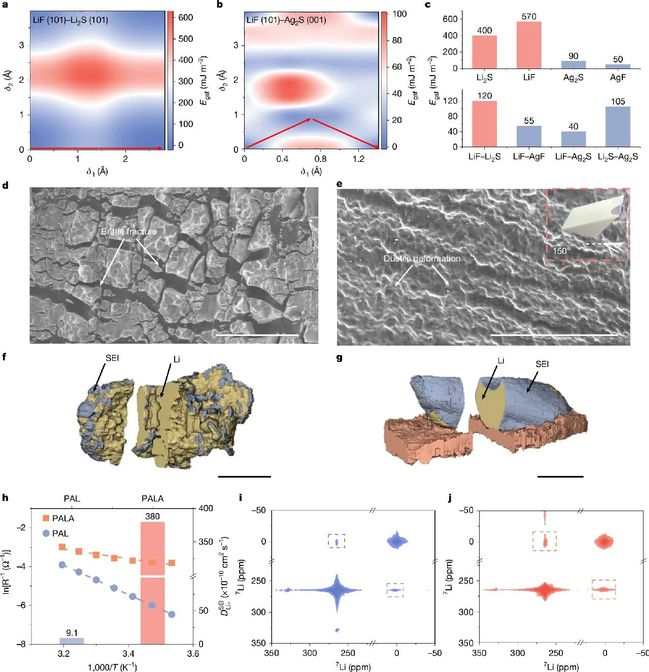

Building upon the screening of target components for the ductile SEI, the research team designed an composite solid-state electrolyte containing AgNO₃ additive and Ag/Li₆.₇₅La₃Zr₁.₅Ta₀.₅O₁₂ (LLZTO) filler. This system enables in situ replacement reactions during solid-state battery operation, converting brittle Li₂S/LiF components into ductile Ag₂S/AgF phases to construct a multi-layer SEI with a soft exterior and rigid interior structure. In this architecture, the outer ductile Ag₂S/AgF layer dissipates interfacial stress, the intermediate layer rich in conventional SEI components maintains high modulus, while the inner lithiophilic layer guides uniform lithium metal deposition. This multi-layer SEI design functions like customized ductile armor for the lithium metal anode, simultaneously ensuring structural integrity under low-temperature and high-current-density conditions while enabling efficient ion transport and suppressing side reactions.

At the same time, the Ag-decorated LLZTO mixed ion-electron conductor ceramic filler (Ag/LLZTO) significantly enhances the bulk dielectric properties of the composite solid electrolyte, establishing efficient lithium-ion transport pathways that facilitate rapid and homogeneous lithium deposition. Experimental results demonstrated exceptional electrochemical performance enabled by this ductile SEI: symmetrical lithium cell with such an SEI has a long cycle life of over 4,500 hours at room temperature when the cycling current density and areal capacity are increased to 15 mA cm−2 and 15 mAh cm−2 respectively. The ductile SEI also works over 7,000 hours at -30 °C, even under practical conditions 5 mA cm−2 and 5 mAh cm−2. When paired with LiNi₀.₈Co₀.₁Mn₀.₁O₂ cathodes in full cells, the system also exhibits remarkable high-rate (20 C) and low-temperature (-30°C) electrochemical performance.

Figure 3. Superior deformability and mechanical stability of the ductile inorganic-rich SEI.

This work broke through the traditional design philosophy of the SEI, which primarily emphasizes hardness, and innovatively introduced ductility as a key characteristic indicator. It proposed a precise pathway from the design of solid electrolyte components to the ideal construction of interfaces, offering a novel strategy to address interfacial cracking issues in solid-state batteries. Additionally, it provided an important theoretical foundation for the design of new types of interfacial layers, holding significant practical value for the development of practical solid-state batteries.

The corresponding authors of the paper are Kang Feiyu, He Yanbing, Lv Wei, Hou Tingzheng, and Yang Quanhong. The co-first authors are Mi Jinshuo (Ph.D. Class of 2025), Yang Jun (Master’s student enrolled in 2023), Chen Likun (Ph.D. Class of 2024) and Cui Wenting (Ph.D. candidate enrolled in 2022), all from Tsinghua Shenzhen International Graduate School. Other contributors include associate professor Gan Lin and associate professor Liu Ming from Tsinghua SIGS, assistant professor Han Bing from the Eastern Institute of Technology, Ningbo, and associate professor Huang Yanfei from Shenzhen University. The research received support from several national and Shenzhen municipal research projects.

Full article:

https://www.nature.com/articles/s41586-025-09675-8

Edited by Chen Jundou

Reviewed by He Yanbin, Jin Shuo, Lin Zhoulu and Nie Xiaomei