The fight against the novel coronavirus has led to a shortage of face masks – an essential item to help control the spread of epidemic. While single-use, surgical masks and medical protective masks typically use PP meltblown filter fibers as an effective filtering layer, once sterilized, static electricity is eliminated and the mask’s protective effect deteriorates. At this critical moment, there is great demand for high-performance face masks in the market.

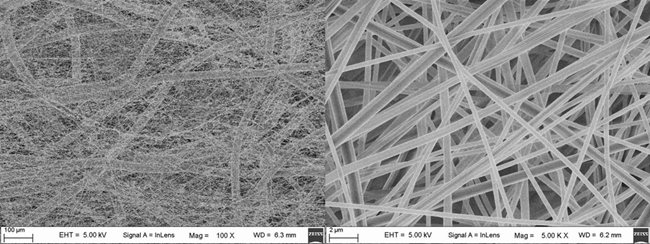

In recent years, Li Bo’s research team from Tsinghua SIGS and Associate Professor Wu Hui’s team from the School of Materials Science and Engineering (SMSE) at Tsinghua University have been working on the development of nanofiber materials. They found that nanofiber membranes exhibit good filtering quality, and quickly started to develop filter material for masks after news of the outbreak.

Through experiments, the team found that non-static physical filtration can be achieved with the ultra-fine diameter and high density of air-spun nanofibers. The resulting material has high filtering efficiency and low air-resistance, meeting the technical requirements of protective face masks for medical use. Its functions can still be maintained after being steamed and sterilized repeatedly, satisfying the public’s urgent demand for reusable masks.

The material is currently undergoing third-party testing in hopes to enter the market as soon as possible.

Edited by Karen Lee